Power Battery System: Working Principle and Components

2024-12-30

Power Battery System: Working Principle and Components

In modern society, with the rapid development of new energy vehicles, the power battery system, as its core component, plays a crucial role. It not only affects the vehicle's cruising range but also directly relates to the car's performance and safety. This article will detail the working principle and main components of the power battery system, helping readers better understand this key technology.

I. Working Principle of the Power Battery System

The working principle of the power battery system is based on electrochemical principles, directly converting chemical energy into electrical energy. Its core lies in the chemical reactions inside the battery, a reaction that can occur under controllable conditions, thus achieving energy storage and release.

Power battery systems usually consist of multiple individual cells, which are connected in series or parallel to form a battery pack. When the external circuit is closed, the chemical reaction inside the battery pack begins, the positive electrode material releases electrons, flowing to the negative electrode through the external circuit, while ions in the electrolyte move within the battery to maintain charge balance. The energy released in this process is electrical energy, which can drive the electric motor and power the vehicle.

During discharge, the chemical energy inside the battery gradually converts into electrical energy and heat energy. When an external power supply is connected, the battery can be charged, at which point electrical energy is converted into chemical energy, stored inside the battery for later use.

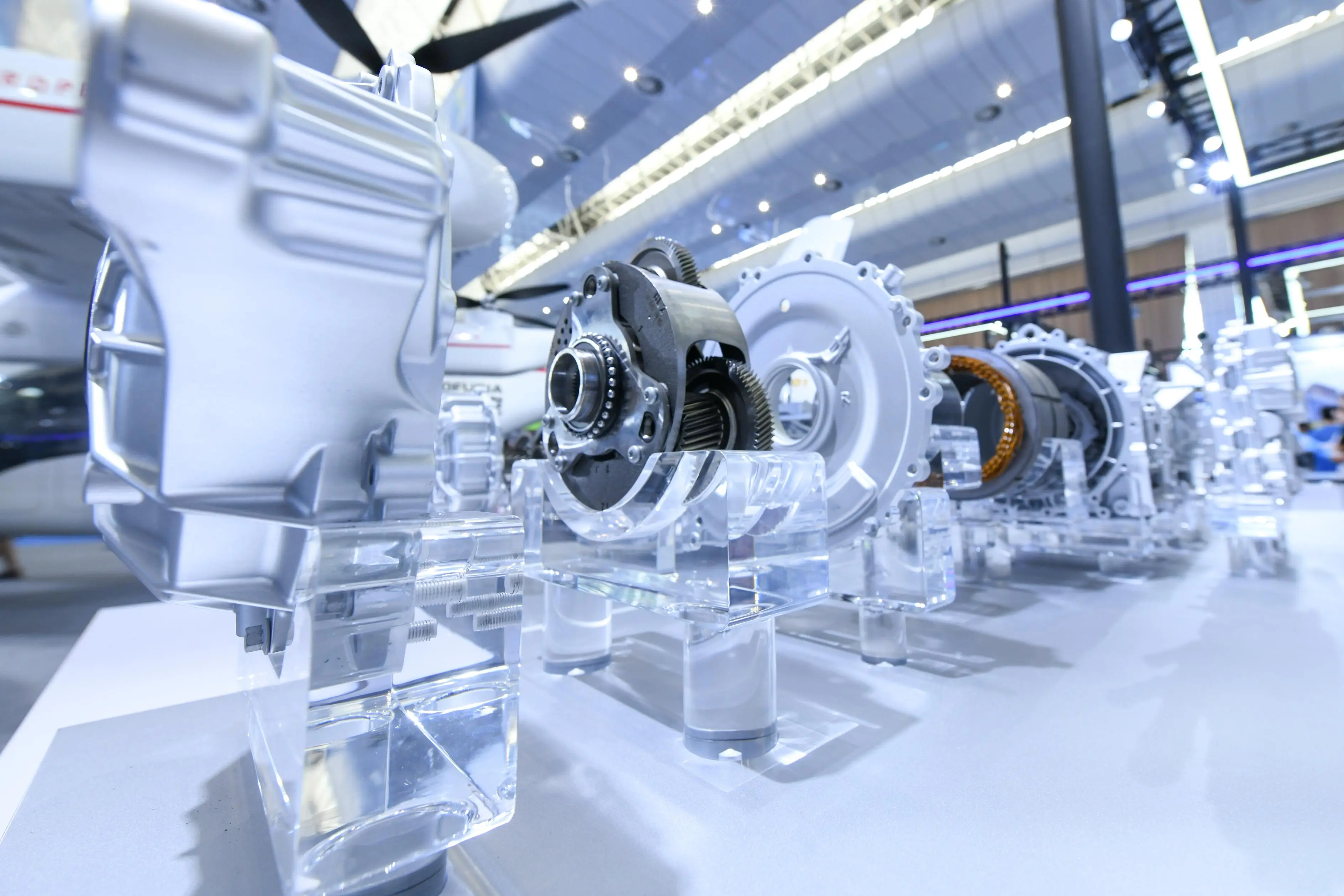

II. Components of the Power Battery System

A power battery system is a complex system composed of several key components, each playing an irreplaceable role. The following are its main components:

1. Individual Battery Cells

Individual battery cells are the basic units of the power battery system, and their performance directly determines the performance of the entire battery pack. Currently, common types of individual battery cells on the market include lithium-ion batteries and nickel-metal hydride batteries. Among them, lithium-ion batteries have become the mainstream choice in the new energy vehicle field due to their high energy density, long cycle life, and environmental friendliness.

The interior of an individual battery cell contains key materials such as the positive electrode, negative electrode, electrolyte, and diaphragm. The positive electrode material usually has high activity and can release a large number of electrons; the negative electrode material has excellent electron acceptance capabilities; the electrolyte is responsible for transferring ions inside the battery to maintain charge balance; and the diaphragm isolates the positive and negative electrodes, preventing short circuits.

2. Battery Management System (BMS)

The battery management system is the "brain" of the power battery system, responsible for monitoring and managing the operating status of the battery pack. It can collect key parameters such as voltage, current, and temperature of the battery pack in real-time, process and analyze the data, and thus achieve precise control of the battery pack.

The BMS also has fault diagnosis and warning functions, capable of promptly detecting and handling abnormal situations in the battery pack, such as overcharging, over-discharging, or overheating of individual cells, ensuring the safe operation of the battery pack. In addition, the BMS can intelligently adjust the output power of the battery pack according to the actual needs of the vehicle, improving energy utilization efficiency.

3. Thermal Management System

The thermal management system is another important component of the power battery system, responsible for maintaining the battery pack's operating temperature within a suitable range. Since the battery generates a large amount of heat during charging and discharging, improper temperature control may lead to reduced battery performance, shortened lifespan, or even safety accidents.

Thermal management systems typically use liquid cooling, air cooling, or phase-change materials for heat dissipation. Liquid cooling removes the heat generated by the battery pack by circulating coolant; air cooling uses fans to blow across the surface of the battery pack to accelerate heat dissipation; and phase-change materials can change phase after absorbing heat, thereby achieving a heat dissipation effect. These methods have their own advantages and disadvantages, and the actual application needs to be selected according to the characteristics of the battery pack and the vehicle's operating environment.

4. Electrical Connectors and Housing

Electrical connectors connect individual cells into a battery pack and ensure stable transmission of current and signals. They are usually made of highly conductive materials and have good corrosion resistance and mechanical strength. The housing protects the battery pack from external environmental interference and also needs to have good heat dissipation performance.

In summary, the power battery system is a complex system consisting of multiple key components. Its working principle is based on electrochemical principles, achieving energy storage and release through chemical reactions. In practical applications, we need to fully understand the components and working principles of the power battery system to better maintain and care for it, ensuring the safe and efficient operation of new energy vehicles.

Key words:

Related News